From development to manufacturing: Process intensification of liquid/gas enzymatic reactions can be executed by implementing continuous manufacturing technology, from development to construction and start-up of a manufacturing plant.

Background

O2 dependent biotransformation reactions have proven difficult in fine chemical manufacturing due to the mass transfer limitations of supplying O2 to the enzymatic reaction, hence affecting the level of efficiency achieved. Previous research has shown that enzymatic processes involving gases have a high potential for process intensification by implementing continuous flow processing technology.

Technology

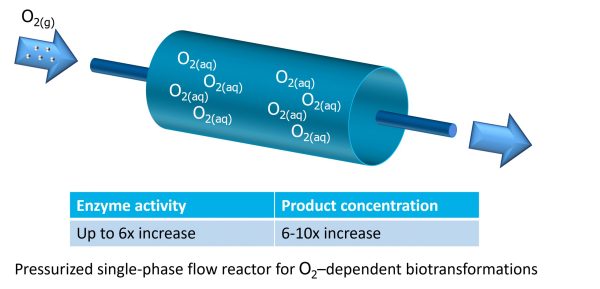

In a cooperation between acib and partner Microinnova Engineering GmbH, with more than 15 years of experience in flow chemistry it has been proven that process intensification can be applied using continuous flow processing. This technology offers a comprehensive solution with a pressurized system that results in a significantly higher level of dissolved oxygen. A continuous flow reactor pressurized to 34 bar enables biotransformation to be conducted in a single liquid phase and significant increase of enzymatic activity was detected already at 10 bar. For glucose oxidase, the intensification factor for enzyme activity was up to 2.5 and amino acid oxidase showed an intensification factor up to 6 for the enzyme activity. High product concentration has been demonstrated with the concentration being 6 to 10 times higher at 34 bars compared to atmospheric pressure.

Project Offer

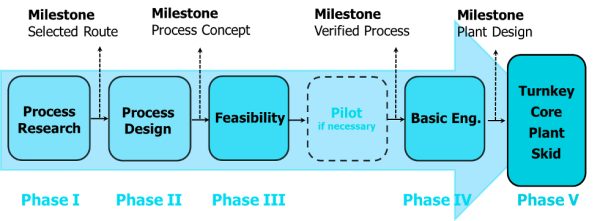

A stepwise approach for realizing an intensified enzymatic process is offered and visualized in the diagram below. This is executed starting from process research and process design. Subsequently, in phase III (feasibility phase) the process is optimized and the performance is verified. Finally the results are used to design and build a manufacturing plant to realize the continuous process on an industrial scale.

Experts:

Prof. Bernd Nidetzky, Dr. Dirk KirschneckAvailable for:

Joint Research Project, Contract Research, Realization of ManufacturingStatus of the project proposal:

Status of the project proposal – Technology Readiness Level 4-5IPR:

Will be generated for our industrial partnerKeywords:

Liquid/Gas, Enzymatic Reactions, Flow chemistry, O2-dependent biotransformation, Continuous manufacturing, Process intensification

Picture credits: Shutterstock