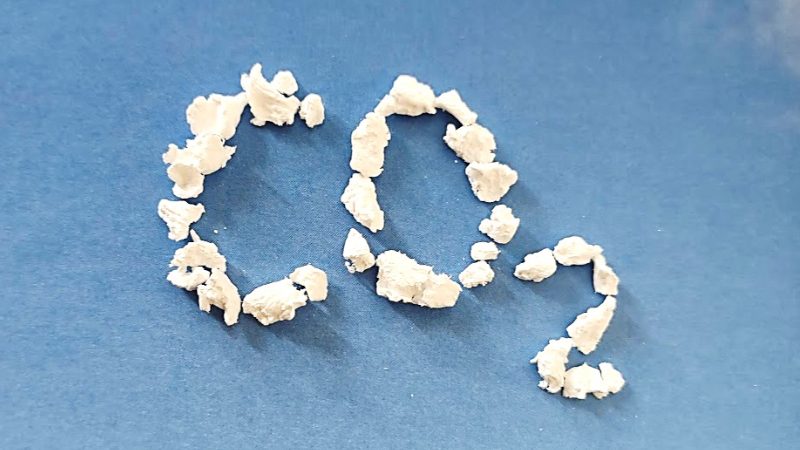

acib in cooperation with Graz University of Technology has developed a method for automatic production of bioplastics from CO2. The CO2 from exhaust gases is assimilated by bacteria and converted into biodegradable natural polymers.

Background

Technology

acib exploits Cupriavidus necator (aka Ralstonia eutropha), a fast-growing bacterium able to use H2 (e.g. from electrolysis of water using excess of electric energy), O2 and CO2 for growth and PHA formation**. A highly automated process for the production of top quality PHA from CO2 is already available (TRL 4 – Technology validated in lab). We now strive to valorise CO2-rich off-gases from industrial processes and to produce innovative, biodegradable plastic products with new partners.

*Illustration Kratzer, R.

**Lambauer, V., Kratzer, R. (2022) Lab-scale cultivation of Cupriavidus necator on explosive gas mixtures: carbon dioxide fixation into polyhydroxybutyrate. Bioengineering, 9:204; DOI.org/10.3390/bioengineering9050204

Offer

acib seeks investors and industrial partners to develop this technology to commercial scale. We are addressing the CO2-producing industry, plant engineering companies and those interested in bioplastics. Under protection of a CDA/NDA we provide you with details on advanced biopolymer productions. Any IP developed in a joint project would fully belong to the new investor/industrial partner.

Experts:

Prof. Dr. Regina Kratzer, Prof. Dr. Markus Reichhartinger, DI Vera LambauerAvailable for:

Joint Research Project, Contract Research, InvestmentsDevelopment status:

Technology Readiness Level 4 (Technology validated in the lab)IPR:

Will be generated for you as our industrial partner / investorKeywords:

CO2-Recycling, PHA, PHB, Bioplastics, Exhaust gas, Biodegradable, Cupriavidus necator